|

New!

Nanotech Scenario Series

Join the

conversation at

CRNtalk!

| |

2007 Newsletter Archives

Subscribe to the

C-R-Newsletter!

Note: The Center for

Responsible Nanotechnology was an affiliate of

World Care, an international,

non-profit, 501(c)(3) organization. The opinions expressed by CRN in our

newsletters and elsewhere do not necessarily reflect those of World Care.

#49

(February 6)

#50

(February 28)

#51

(March 31)

#52 (April

30)

#53 (May

31)

#54 (June

29)

#55 (August

10)

#56 (August 31)

#57

(September 29)

#58

(October 31)

#59

(November 30)

#60

(December 28)

2003

Archives

2004 Archives

2005 Archives

2006 Archives

2008 Archives

C-R-Newsletter #60:

December 28, 2007

Our Fifth Anniversary

CRN Scenarios Published

Roadmap Now Available

IEEE Urges MM Funding

The Age of Nanotechnology

Creating Nanotech

Communities

Ranking the Risks

Feature Essay: Restating CRN’s

Purpose

Editor’s Note:

Even by our usual busy standards, this has been a remarkably active month -- and

year! -- for CRN. To keep up with all the latest happenings on a daily basis,

be sure to check our

Responsible Nanotechnology weblog.

==========

Our Fifth Anniversary

It has been five years now since Mike Treder and Chris Phoenix

founded the Center for Responsible Nanotechnology in

December 2002. In next month’s newsletter, we’ll publish an overview of our

accomplishments, our disappointments, and our plans for the future. We would

have offered that assessment this month, except we’ve been too busy with

everything else that’s going on!

Below you’ll read about this month’s publication of eight detailed

nanotechnology scenarios that CRN developed, the release of an important

molecular manufacturing roadmap, new books that contain contributions from CRN,

several new articles we have posted on the Web, and more. It’s an exciting time

to be involved with emerging technologies, and a time when we -- all of us --

are faced with many difficult decisions about managing powerful new

capabilities. We appreciate your continued interest, and

your support for our efforts.

CRN Scenarios Published

On December 11, we released our long-awaited series of nanotechnology scenarios

depicting various versions of a near-future world into which transformative

manufacturing concepts may emerge. Across eight separate storylines, an

international team of policy, technology,

and economic specialists organized by CRN imagined in detail a range of

plausible, challenging events -- from pandemics to climate crises to

international conflicts -- to see how they might affect the development of

advanced nanotechnology over the next 15 years.

All eight scenarios, plus an introduction putting them into context, were

posted online at Nanowerk.com, as well on CRN’s

main website. The scenarios also will be published in the peer-reviewed

print journal,

Nanotechnology Perceptions, beginning early next year.

In pursuing this ambitious project, we pulled together more than 50 people from

six continents, with a range of backgrounds and points of view, as

collaborators. Over the course of several months, a unique series of “virtual

workshops” -- using a combination of teleconferencing, Internet chat, and online

shared documents -- produced eight intriguing scenarios. We hope you’ll find

them stimulating and encourage you to offer feedback by joining the conversation

at our new

CRN-Talk group discussion site.

Roadmap Now Available

After two and a half years, and numerous meetings pulling together dozens of

researchers, the “Technology

Roadmap for Productive Nanosystems” has finally been made available to the

public. We offer congratulations to the steering committee, to the sponsors, and

especially to the many workshop and working group participants who tirelessly

devoted their time and talents to this important undertaking.

Combined with the remarkable progress of the British

IDEAS Factory, and the U.S. government report calling for

increased funding of research toward bottom-up

molecular manufacturing, it's clear that things are moving rapidly forward.

CRN's oft-criticized timeline for development of desktop nanofactories seems

less extreme with each passing year. (For more on that, see our

Feature Essay below.)

IEEE Urges MM Funding

It's worth paying attention when a large and respected organization such as the

IEEE

-- the world's largest professional technology association --

publicly takes a stand

calling for funding of research related to molecular manufacturing (MM), also

known as molecular nanotechnology.

A recent article on the IEEE’s Tech Talk blog states:

Proposed funding for further research into the potential of

molecular nanotechnology is overdue and hopefully will lead to some productive

research in this field. . . Hopefully, the combination of announced funding and

a research agenda will remove much of the speculation and acrimony that seems to

have surrounded molecular nanotechnology and just bring it to where it should

have been all along: a field of scientific endeavor.

READ MORE...

The Age of Nanotechnology

Another new book on nanotechnology has been published that includes a chapter we

contributed. The book is

The Age of Nanotechnology, edited by Nirmala Rao Khadpekar. It was

published in India, but contains items written by both Indian researchers and by

others from around the world. Our chapter is titled "Bridges to Safety, and

Bridges to Progress" -- an updated version of this

paper, which you can download from our website.

Other recent books that contain contributions from CRN include

Worldchanging: A

Users Guide for the 21st Century, edited by Alex Steffen, and

Nanoethics, edited

by Fritz Allhoff, Patrick Lin, James Moor, and John Weckert.

Creating Nanotech Communities

CRN has posted another column to the popular

Nanotechnology Now web

portal, this time authored by our new Director of

Research Communities, Jessica Margolin. Her article is titled "Creating

Productive Nanotech Communities." Here is the abstract:

Moving forward into a rapidly changing world and making good

decisions about safe development and responsible use of advanced nanotechnology

will require the creation of healthy, diverse, productive communities of

nanotech researchers, students, policy analysts, and interested observers.

We hope you'll read

all our

columns, offer feedback, and tell others about them too.

Ranking the Risks

On the LinkedIn network,

D.K. Matai, an engineer, entrepreneur and philanthropist, recently posted a list

of 26 areas of serious global risk, and asked people to prioritize them. Here is

part of

the answer offered by CRN Executive Director Mike Treder…

I've divided the listed risks into four levels of declining

concern. On the top level are:

1. Nanotechnology

2. Climate Chaos

3. Environmental Degradation

4. Financial Systemic Risk

Today's nanoscale technologies pose little risk beyond familiar concerns of

chemical toxicity and life-cycle assessment. However, as the field progresses

toward general-purpose atomically-precise exponential manufacturing, it could

present perilous issues ranging from an unstable arms race to severe economic

disruption and more. There are as many potential benefits as there are possible

dangers, of course, so we shouldn't consider halting or slowing nanotech R&D.

What we must do is speed up investigation of the technology's powerful

implications and seriously explore various options for international regulation.

Climate chaos already is causing environmental degradation and this will only

get worse, possibly much worse and much faster than we are prepared for.

Together these two issues easily could lead to financial systemic failures, and

that process might be further accelerated by ill-advised attempts to deal with

climate change using geoengineering techniques made possible by advanced

nanotechnology, with unforeseen consequences causing the whole assemblage to

spiral out of control.

READ MORE…

Feature Essay: Restating CRN’s Purpose

By Jamais Cascio, Director of Impacts Analysis

How soon could molecular manufacturing (MM) arrive? It's an important question,

and one that the Center for Responsible Nanotechnology takes seriously. In our

recently released series of scenarios for the

emergence of molecular manufacturing, we talk about MM appearing by late in the

next decade; on the CRN main website, we describe MM as being plausible by

as early as 2015. If you follow the broader

conversation online and in the technical media about molecular manufacturing,

however, you might argue that such timelines are quite aggressive, and not at

all the consensus.

You'd be right.

CRN doesn't talk about the possible emergence of molecular manufacturing by

2015-2020 because we think that this timeline is necessarily the most realistic

forecast. Instead, we use that timeline because the purpose of the Center for

Responsible Nanotechnology is not prediction, but preparation.

While arguably not the most likely outcome, the emergence of molecular

manufacturing by 2015 is entirely plausible. A variety of public projects

underway today could, with the right results to current production dilemmas,

conceivably bring about the first working nanofactory within a decade. Covert

projects could do so as well, or even sooner, especially if they've been

underway for some time.

CRN's leaders do not focus on how soon molecular manufacturing could emerge

simply out of an affection for nifty technology, or as an aid to making

investment decisions, or to be technology pundits. The CRN timeline has always

been in the service of the larger goal of making useful preparations for (and

devising effective responses to) the onset of molecular manufacturing, so as to

avoid the worst possible outcomes such technology could unleash. We believe that

the risks of undesirable results increase if molecular manufacturing emerges as

a surprise, with leading nations (or companies, or NGOs) tempted to embrace

their first-mover advantage economically, politically, or militarily.

Recognizing that this event could plausibly happen in the next decade -- even if

the mainstream conclusion is that it's unlikely before 2025 or 2030 -- elicits

what we consider to be an appropriate sense of urgency regarding the need to be

prepared. Facing a world of molecular manufacturing without adequate forethought

is a far, far worse outcome than developing plans and policies for a

slow-to-arrive event.

There's a larger issue at work here, too, particularly in regards to the

scenario project. The further out we push the discussion of the likely arrival

of molecular manufacturing, the more difficult it becomes to make any kind of

useful observations about the political, environmental, economic, social and

especially technological context in which MM could occur. It's much more likely

that the world of 2020 will have conditions familiar to those of us in 2007 or

2008 than will the world of 2030 or 2040.

Barring what Nassim Nicholas Taleb calls "Black

Swans" (radical, transformative surprise developments that are extremely

difficult to predict), we can have a reasonable image of the kinds of drivers

the people of a decade hence might face. The same simply cannot be said for a

world of 20 or 30 years down the road -- there are too many variables and

possible surprises. Devising scenarios that operate in the more conservative

timeframe would actually reduce their value as planning and preparation tools.

Again, this comes down to wanting to prepare for an outcome known to be almost

certain in the long term, and impossible to rule out in the near term.

CRN's Director of Research Communities Jessica Margolin noted in conversation

that this is a familiar concept for those of us who live in earthquake country.

We know, in the San Francisco region, that the Hayward Fault is

near-certain to unleash

a major (7+) earthquake sometime this century. Even though the mainstream

geophysicists' view is that such a quake may not be likely to hit for another

couple of decades, it could happen tomorrow. Because of this, there are public

programs to educate people on what to have on hand, and wise residents of the

region have stocked up accordingly.

While Bay Area residents go about our lives assuming that the emergency bottled

water and the batteries we have stored will expire unused, we know that if that

assumption is wrong we'll be extremely relieved to have planned ahead.

The same is true for the work of the Center for Responsible Nanotechnology. It

may well be that molecular manufacturing remains 20 or 30 years off and that the

preparations we make now will eventually "expire." But if it happens sooner --

if it happens "tomorrow," figuratively speaking -- we'll be very glad we started

preparing early.

C-R-Newsletter #59:

November 30, 2007

Military Nanotechnology Book

Review

Nano Risk Perception

Modular Models of Molecular

Manufacturing

Shifting International Orders

Acid, Oceans, and Oil

Context is Everything

Feature Essay: Imagining the

Future

Every month

is full of activity for CRN. To follow the latest happenings on a daily basis,

be sure to check our

Responsible Nanotechnology weblog.

==========

Military Nanotechnology Book Review

The

current issue of the Bulletin of the Atomic Scientists includes a

review by Mike Treder, CRN Executive Director, of Jürgen Altmann's important new

book,

Military Nanotechnology: Potential Applications and Preventive Arms Control.

Here is how the article begins:

Deeply researched and carefully worded, Military Nanotechnology is an

overview of an emerging technology that could trigger a new arms race and

gravely threaten international security and stability. Jürgen Altmann's

academic style allows the reader to assess nanotechnology's perilous military

implications in plain, dispassionate terms. What we face might sound like

science fiction, but, in this book, we have the facts laid bare, and they are

hair-raising enough without embellishment.

You can download the full review

as a PDF, or look for November/December issue of the magazine at your local

bookstore or library.

Nano Risk Perception

At his excellent Nanowerk site,

Michael Berger writes:

The benefits of new technologies, whether they are new medical treatments, an

innovative approach to farming or new ways of generating energy, almost always

come with some new risks as well. In the emerging stages of a new technology,

experts and the public generally differ in their perceptions of risk... It is

not surprising that a new study found that, in general, nanoscientists are

more optimistic than the public about the potential benefits of

nanotechnology. What is surprising though, is that, for some issues related to

the environmental and long-term health impacts of nanotechnology,

nanoscientists seem to be significantly more concerned than the public.

We

think there is something else revealed by

the study Berger cites, which is that scientists and the public are thinking

about two different kinds of nanotechnology.

Health-related risks and pollution issues are both more typically associated

with current and near-future

nanoscale technologies, while concerns about privacy erosion, economic

disruption, and a new arms race are more often connected with longer-term

advanced nanotechnology, i.e. molecular manufacturing.

So, the

differing responses are not really a surprise at all, if it's understood

that each group is considering risks related to technology levels that are

vastly different in terms of power and potential.

Modular Models of Molecular Manufacturing

In a

recent article on CRN’s Responsible Nanotechnology blog, Nato Welch writes

about the new “BUG”

modular hardware platform and discovers some insights for the future of

molecular manufacturing. He compares the modular

hardware approach with

Tom Craver’s

proposal for “nanoblock” use inside nanofactories:

Each nanoblock could be anything -- motors, computers, sensors, memory, etc.

The major differences are that nanoblocks would, of course, be much smaller,

would be built to atomically-precise specifications, and would have to be

assembled by a fabrication device designed for the nanoblock scale, rather

than being hand-assembled. The striking similarities between Craver's

nanoblocks model and the BUG platform suggests to me that we don't even need

to presuppose atomically-precise manufacturing in order to design and deploy

the kind of infrastructure Craver suggests... When it arrives, molecular

manufacturing could be designed to just plug in to existing fabrication

standards already developed for larger-scale systems in the meantime.

Shifting International Orders

In the last 100 years, our world has experienced several huge shifts of social,

economic, political, and military power. These transitions took place at the

ends of World War I, World War II, and the Cold War. Before, between, and after

each of those shifts, international order was relatively stable. But within the

lifetimes of many people living today, three titanic rearrangements of global

power have taken place.

Will it happen again? Almost certainly. The big question is when, and how?

In an entry on CRN’s blog, we distinguish

four different international orders that have prevailed during the previous

100 years: The Age of Modern Empires (before ~1920), The Rise and Fall of

Fascism (~1920 to ~1950), Cold Wars (~1950 to ~1990), and Unipolar Power (~1990

to the present).

If you accept the argument that we're living today in the fourth different

period of the last 100 years, it should be obvious that this is not a permanent

state. So, what comes next? How can we anticipate it? How might we shape it? And

how will the development of powerful new technologies, such as

molecular manufacturing, fit into that big picture?

Acid, Oceans, and Oil

Over at the WorldChanging site,

Emily Gertz reminds us:

Some of the most profoundly disturbing climate crisis news this year has been

the growing evidence that the planet's natural systems for absorbing

greenhouse gas out of the atmosphere, particularly the oceans, are beginning

to fail. There's simply more carbon dioxide in the atmosphere than these

powerful sinks can uptake.

While in a

related article on the Wired blog network, we read about the end of

oil:

If there are any lingering doubts as to whether the age of oil is nearing its

end, the International Energy Agency has put them to rest and made it clear

that only a massive and immediate investment in sustainable energy will

prevent a global crisis.

So, we're running out of cheap oil at the same time that global energy demand is

skyrocketing. And as we're pouring more greenhouse gases into the air, the

atmosphere and the oceans are

becoming less able to recycle those gases.

These are two separate but related crises:

1. We need much more energy, but it's becoming less available and more

expensive.

2. Damage to the ecosphere from energy use is rapidly becoming more severe.

Is there a simple solution to both of these complex problems? Almost certainly

not. Some will suggest heavy investment in

nuclear energy; some will say conversion to

solar, wind, or geothermal energy is the answer; some few will recommend

drastically scaling back society's energy demands; still others will say

that we must embark on

radical "re-terraforming" of the Earth.

Finally, there is the whole question of whether we should just admit that

climate change can't be stopped, and begin figuring out

how to live with it. We may not be that far gone yet, but the signs aren't

looking good.

Context is Everything

Sometimes when we write about climate change (see above),

or geopolitics, or privacy erosion,

we’re criticized for straying too far from CRN’s primary topic: safe

development and responsible use of molecular manufacturing.

The explanation for this has to do with how we are, over time, coming to see

that the issues CRN is nominally concerned with are inextricably linked with a

wide range of other topics.

Molecular manufacturing will not be developed in a

vacuum, nor will it emerge unhindered into a welcoming world. How, when, or even

whether desktop nanofactories are finally produced will depend largely on

external factors that have little or nothing to do with nanotech. This is a big

drive behind our efforts to create a series of

professional-quality scenarios about the near-future development of

molecular manufacturing within the context of projected trends in science,

technology, and global politics.

The task of designing effective policy toward safe development and responsible

use of advanced nanotechnology is both highly complex and vitally important. A

broad base of knowledge is required for that,

including as good an understanding as we can get of the rapidly changing social,

economic, and political systems that atomically-precise exponential

manufacturing eventually will encounter. Those new conditions must be taken into

account, because the world of circa 2020 is expected to be vastly different from

2007 -- and in developing responsible global solutions, context is everything.

Feature Essay: Imagining the Future

By Jamais Cascio, CRN Director of Impacts Analysis

I'm one of the lucky individuals who makes a living by thinking about what we

may be facing in the years ahead. Those of us who follow this professional path

have a variety of tools and methods at our disposal, from subjective

brainstorming to models and simulations. I tend to follow a middle path, one

that tries to give some structure to imagined futures; in much of the work that

I do, I rely on scenarios.

Recently, the Center for Responsible Nanotechnology

undertook a project to develop a variety of scenarios regarding the

different ways in which molecular manufacturing might develop. One of the

explicit goals of that project was to come up with a broad cross-section of

different types of deployment -- and in that task, I think we succeeded.

I'd like to offer up a different take on scenarios for this month's newsletter

essay, however. With the last scenario project, we used "drivers" -- the various

key factors shaping how major outcomes transpired -- consciously intended to

reflect different issues around the development of molecular manufacturing. It's

also possible, however, to use a set of drivers with broader applicability,

teasing out specific scenarios from the general firmament. Such drivers usually

describe very high-level cultural, political and/or economic factors, allowing a

consistent set of heuristics to be applied to a variety of topics.

Recently, I developed a

set of scenarios for a project called "Green Tomorrows." While the scenario

stories themselves concerned different responses to the growing climate crisis,

the drivers I used operated at a more general level -- and could readily be

applied to thinking about different potential futures for

molecular manufacturing. The two drivers, each with two extremes, combine to

give four different images of the kinds of choices we'll face in the coming

decade or two.

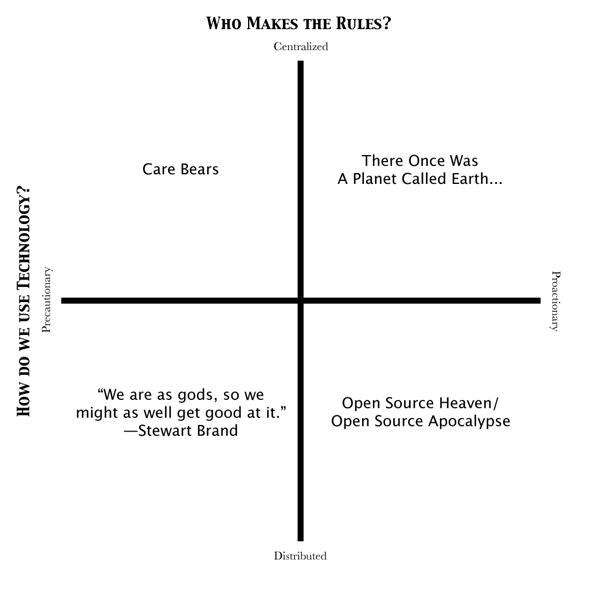

The drivers I chose reflect my personal view that both how we live and how we

develop our tools and systems are ultimately political decisions. The first,

"Who Makes the Rules?", covers a spectrum from Centralized to Distributed. Is

the locus of authority and decision-making limited to small numbers of powerful

leaders, or found more broadly in the choices made by everyday citizens, working

both collaboratively and individually? The second, "How Do We Use Technology?",

runs from Precautionary to Proactionary. Do the choices we make with both

current and emerging technologies tend to adopt a "look before you leap" or a

"he who hesitates is lost" approach?

So, how do these combine?

The first scenario, living in the combination of Centralized rule-making and

Precautionary technology use, is "Care Bears." The name refers to online games

in which players are prevented by the game rules from attacking each other. For

players who want no controls, the rules are overly-restrictive and remove the

element of surprise and innovation; for players who just want an enjoyable

experience, the rules are a welcome relief.

In this scenario, then, top-down rule-making with an emphasis on prevention of

harm comes to slow overall rates of molecular manufacturing progress. The result

is a world where nanotechnology-derived solutions are harder to come by, but one

where nanotechnology-derived risks are less likely, as well. This is something

of a baseline scenario for people who believe that regulation, licensing, and

controls on research and development are ultimately good solutions for avoiding

disastrous outcomes. The stability of the scenario, however, depends upon both

how well the top-down controls work, and whether emerging

capabilities of molecular manufacturing tempt some people or states to grab

greater power. If this scenario breaks, it could easily push into the

lower/right world.

The second scenario, combining Centralized rule-making and Proactionary

technology use, is "There Once Was A Planet Called Earth..." The name sets out

the story fairly concisely: competition between centralized powers seeking to

adopt the most powerful technologies as quickly as possible -- whether for

benign or malignant reasons -- stands a very strong likelihood of leading to a

devastating conflict. For me, this is the scenario most likely to lead to a bad

outcome.

Mutually-assured global destruction is not the only outcome, but the probable

path out of this scenario is a shift towards greater restrictions and controls.

This could happen because people see the risks and act accordingly, but is more

likely to happen because of an accident or conflict that brings us to the brink

of disaster. In such a scenario, increasing restrictions (moving from

proactionary to precautionary) are more likely than increasing freedom (moving

from centralized to distributed).

The third scenario, combining Distributed rule-making and Proactionary

technology use, is "Open Source Heaven/Open Source Apocalypse." The name

reflects the two quite divergent possibilities inherent in this scenario: one

where the spread of user knowledge and access to molecular manufacturing

technologies actually makes the world safer by giving more people the ability to

recognize and respond to accidents and threats, and one where the spread of

knowledge and access makes it possible for super-empowered angry individuals to

unleash destruction without warning, from anywhere.

My own bias is towards the "Open Source Heaven" version, but I recognize the

risks that this entails. We wouldn't last long if the knowledge of how to make a

device that would blow up the planet with a single button-push became

widespread, and some of the arguments around the destructive potential of

late-game molecular manufacturing seem to approach that level of threat.

Conversely, it's not hard to find evidence that open source knowledge and access

tends to offer greater long-term safety and stability than does a closed

approach, and that insufficiently-closed projects leaking out to interested and

committed malefactors (but not as readily to those who might help to defend

against them) offers the risks of opening up without any of the benefits.

Finally, the fourth scenario, combining Distributed rule-making and

Precautionary technology use, is "We Are As Gods, So We Might As Well Get Good

At It." Stewart Brand used that as an opening line for his

Whole

Earth Catalogs, reflecting his sense that the emerging potential of new

technologies and social models gave us -- as human beings -- access to far

greater capabilities than ever before, and that our survival depended upon

careful, considered examination of the implications of this fact.

In this world, the widespread knowledge of and access to molecular manufacturing

technologies gives us a chance to deal with some of the more pressing big

problems we as a planet face -- extreme poverty, hunger, global warming, and the

like -- in effect allowing us breathing room to take stock of what kind of

future we'd like to create. Those individuals tempted to use these capabilities

for personal aggrandizement have to face a knowledgeable and empowered populace,

as do those states seeking to take control away from the citizenry. This is,

admittedly, the least likely of the four worlds, sadly.

But you don't have to take my word for it. This "four box" structure doesn't

offer predictions, but a set of lenses with which to understand possible

outcomes and the strategies that might be employed to reach or avoid them. The

world that will emerge will undoubtedly have elements of all four scenarios, as

different nations and regions are likely to take different paths. The main

purpose of this structure is to prompt discussion about what we can do now to

push towards the kind of world in which we'd want to live, and to thrive.

C-R-Newsletter #58:

October 31, 2007

Productive

Nanosystems Conference

The Nanofactory

Ecosystem

Scenario

Publication Plans

Keeping Tabs on

China

Monstrous Hybrids

Alive

Feynman Prizes

Awarded

Foresight Vision

Weekend

Guest Science

Essay: Exploring the Productive Nanosystems Roadmap

Every month

is full of activity for CRN. To follow the latest happenings on a daily basis,

be sure to check our

Responsible Nanotechnology weblog.

==========

Productive Nanosystems Conference

One of the biggest events of the year in advanced nanotechnology was a recent

conference titled “Productive

Nanosystems: Launching the Technology Roadmap.” The event, organized by the

Society of Manufacturing Engineers, the Foresight Nanotech Institute, and

Battelle, was reported extensively -- almost minute-by-minute -- by CRN's Chris

Phoenix on our blog, and is also the subject of this month’s guest science essay

by Damian Allis (see below). Chris. For your convenience we’ve created

a listing of the superb coverage that Chris provided, including every

presentation at the conference.

The Nanofactory Ecosystem

We’re pleased to report that CRN's latest monthly column for the popular

Nanotechnology Now

web portal was authored by our new Director of

Impacts Analysis, Jamais Cascio. His article is titled "The

Nanofactory Ecosystem." Here is the abstract:

In addition to understanding the progress of nanotechnology

toward building atomically-precise desktop manufacturing systems --

nanofactories -- we also need to consider the infrastructure needed to

sustain that new technology paradigm. What sort of "ecosystem" might spring up

around nanofactories?

We hope you'll read

all our

columns, offer feedback, and tell others about them too.

Scenario Publication Plans

CRN is excited to have an agreement with

Nanotechnology

Perceptions, a peer-reviewed academic journal published by Switzerland's

Collegium Basilea, to begin releasing our

nanotechnology scenario series starting with their November 2007 issue. They

will publish two scenarios in that first issue, then follow with two more in

their March 2008 issue, and conclude with the remaining four scenarios in July

2008. Each issue also will include at least one commentary article from a

"European perspective." Simultaneous with the November 2007 issue of the

journal, all eight of our scenarios will be posted online at the

Nanowerk.com

site, where they also will host a discussion space for readers. We're quite

pleased with both of these arrangements; together they will help us to reach a

wide audience for this important project.

Keeping Tabs on China

At CRN, we spend a lot of time thinking and writing

about China, and we believe with good reason. It's common to hear the last

100 years referred to as "The American Century," and many observers now suggest

that the next 100 years eventually will be known as "The Chinese Century."

Of course, a lot could happen to change that outcome. For one thing, China faces

huge internal and external challenges on its path to global supremacy. For

another, the United States is still the preeminent superpower in both economic

and military terms and is likely to remain so for some time.

But in looking outward over the next several decades, it's hard to conceive a

plausible scenario of world development that does not include China in some

capacity. So, as we try to envision how, where, and when molecular manufacturing

will emerge and what its implications will be, we

must include China in our calculations of context.

READ MORE…

Monstrous Hybrids Alive

What's the most important book you could read that's not about science or

technology to gain a better understanding of CRN's work?

One strong candidate would be

Systems of Survival

by the late great social scientist Jane Jacobs. Although the book itself is not

especially readable (our “Three Systems” paper

includes the most important stuff), her ideas are profound.

Another book we've frequently recommended is Jim Garrison's

America as Empire: Global

Leader or Rogue Power? It offers a compelling review of previous

historical empires, their rise and fall, and compares them with the U.S. today.

Most relevant to CRN's work is Garrison's prescription for something he calls

network democracy.

Now, we may have a third title to add to this short list:

The Shock Doctrine: The Rise

of Disaster Capitalism by Naomi Klein. I don't have the book yet, but

from what I've heard it looks like a must-read, with a lot to say about the

unstable global future into which molecular manufacturing may emerge in the next

decade or two.

READ MORE…

Feynman Prizes Awarded

Every year, the Foresight Institute awards prizes to leaders in research,

communication and study in the field of nanotechnology. Prizes are conferred on

individuals whose work in research, communication and study are moving society

toward the ultimate goal of atomically-precise manufacturing.

This year's

winners are:

Theory Prize - David Leigh, University of Edinburgh, UK

Experimental Prize - Fraser Stoddart, UCLA

Communication Prize - Robert A Freitas Jr., Institute for Molecular

Manufacturing

Distinguished Student Prize - Fung-Suong Ou, Rice University

Congratulations to all!

Foresight Vision Weekend

Previous editions of the annual fall conference presented by the Foresight

Nanotech Institute have been open only to their "senior associates." But this

year, they're opening up the event to related groups, including people involved

with CRN. It's got a wide-open format this time too (it’s described as an

“un-conference”) with a very broad topic list. For more information on the

November 3-4 event in Sunnyvale, California,

click here.

Guest Science Essay: Exploring the Productive Nanosystems Roadmap

Damian Allis, Research Professor of Chemistry at Syracuse University and Senior

Scientist for Nanorex, Inc.

What follows is a brief series of notes and observations about the

Roadmap Conference,

some of the activities leading up to it, and a few points about the state of

some of the research that the Roadmap is hoping to address. All views expressed

are my own and not necessarily those of other Roadmap participants,

collaborators, my affiliated organizations (though I hope to not straddle that

fine line between "instigation" and "inflaming" in anything I present below).

Some Opening Praise for Foresight

There are, basically, three formats for scientific conferences. The first is

discipline-intensive, where everyone attending needs no introduction and

certainly needs no introductory slides (see the division rosters at most any

National ACS conference). The

only use of showing an example of

Watson-Crick base pairing

at a DNA nanotechnology conference of this format is to find out who found the

most aesthetically-pleasing image on "the Google."

There is the middle ground, where a single conference will have multiple

sessions divided into half-day or so tracks, allowing the carbon nanotube

chemists to see work in their field, then spend the rest of the conference

arguing points and comparing notes in the hotel lobby while the DNA scientists

occupy the conference room. The

FNANO

conference is of a format like this, which is an excellent way to run a

conference when scientists dominate the attendee list.

Finally, there is the one-speaker-per-discipline approach, where introductory

material consumes roughly 1/3 of each talk and attendees are given a taste of a

broad range of research areas. Such conferences are nontrivial to organize for

individual academics within a research plan but are quite straightforward for

external organizations with suitable budgets to put together.

To my mind, Foresight

came close to perfecting this final approach for nanoscience over the course of

its annual Conferences on Molecular Nanotechnology. Much like the organizational

Roadmap meetings and the Roadmap conference itself, these Foresight conferences

served as two-day reviews of the entire field of nanoscience by people directly

involved in furthering the cause. In my own case, research ideas and

collaborations were formed that continue to this day that I am sure would not

have otherwise. The attendee lists were far broader than the research itself,

mixing industry (the people turning research into products), government (the

people turning ideas into funding opportunities), and media (the people bringing

new discoveries to the attention of the public). Enough cannot be said about the

use of such broad-based conferences, which are instrumental in endeavors to

bring the variety of research areas currently under study into a single focus,

such as in the form of a technology Roadmap.

Why A "Productive Nanosystems" Roadmap?

The semiconductor industry

has its Roadmap. The

hydrogen storage community has its Roadmap. The

quantum computing and

cryptography

communities have their Roadmaps. These are major research and development

projects in groundbreaking areas that are not in obvious competition with one

another but see the need for all to benefit from all of the developments within

a field (in spirit, anyway). How could a single individual or research group

plan 20 years into the future (quantum computing) or plan for the absolute limit

of a technology (semiconductor)?

The

Technology Roadmap for Productive Nanosystems falls into the former

category, an effort to as much take a snapshot of current research and very

short-term pathways towards nanosystems in general as it is to begin to plot

research directions that take advantage of the continued cross-disciplinary

efforts now begun in National Labs and large research universities towards

increasing complexity in nanoscale study.

On one far end of the spectrum, the "productive nanosystem" in all of its

atomically-precise glory as envisioned by many forward-thinking scientists is a

distant, famously debated, and occasionally ridiculed idea that far exceeds our

current understanding within any area of the physical or natural sciences. Ask

the workers on the first Model T assembly line how they expected robotics to

affect the livelihoods and the productivity of the assembly lines of their

grandchildren's generation, and you can begin to comprehend just how

incomprehensible the notion of a fully developed desktop nanofactory or medical

nanodevice is even to many people working in nanoscience.

On the other end of the spectrum (and the primary reason, I think, in molecular

manufacturing), it seems rather narrow-minded and short-sighted to believe that

we will never be able to control the fabrication of matter at the atomic scale.

The prediction that scientists will still be unable in 50 years to abstract a

carbon atom from a diamond lattice or build a computer processing unit by

placing individual atoms within an insulating lattice of other atoms seems

absurd. That is, of course, not to say that

molecular

manufacturing-based approaches to the positional control of individual atoms

for fabrication purposes will be the best approach to generating various

materials, devices, or complicated nanosystems (yes, I'm in the field and I

state that to be a perfectly sound possibility).

To say that we will never have that kind of control, however, is a bold

statement that assumes scientific progress will hit some kind of technological

wall that, given our current ability to manipulate individual hydrogen atoms

(the smallest atoms we have to work with) with positional control on atomic

lattices, seems to be sufficiently porous that atomically precise manufacturing,

including the mechanical approaches envisioned in molecular manufacturing

research, will continue on undaunted. At the maturation point of all possible

approaches to atomic manipulation, engineers can make the final decision of how

best to use the available technologies. Basically and bluntly, futurists are

planning the perfect paragraph in their heads while researchers are still

putting the keyboard together. That, of course, has been and will always

be the case at every step in human (and other!) development. And I mean that in

the most positive sense of the comparison. Some of my best friends are futurists

and provide some of the best reasons for putting together that keyboard in the

first place.

Perhaps a sea change over the next ten years will involve molecular

manufacturing antagonists beginning to agree that "better methods exist for

getting A or B" instead of now arguing that "molecular manufacturing towards A

and B is a waste of a thesis."

That said, it is important to recognize that the Technology Roadmap for

Productive Nanosystems is not a molecular manufacturing Roadmap, rather a

Roadmap that serves to guide the development of nanosystems capable of atomic

precision in the manufacturing processes of molecules and larger systems. The

difference is largely semantic, though, founded in the descriptors of molecular

manufacturing as some of us have come to know and love it.

Definitions!

If we take the working definitions from the Roadmap...

Nanosystems are interacting nanoscale structures, components, and

devices.

Functional nanosystems are nanosystems that process material, energy, or

information.

Atomically precise structures are structures that consist of a specific

arrangement of atoms.

Atomically precise technology (APT) is any technology that exploits

atomically precise structures of substantial complexity.

Atomically precise functional nanosystems (APFNs) are functional

nanosystems that incorporate one or more nanoscale components that have

atomically precise structures of substantial complexity.

Atomically precise self-assembly (APSA) is any process in which

atomically precise structures align spontaneously and bind to form an atomically

precise structure of substantial complexity.

Atomically precise manufacturing (APM) is any manufacturing technology

that provides the capability to make atomically precise structures, components,

and devices under programmable control.

Atomically precise productive nanosystems (APPNs) are functional

nanosystems that make atomically precise structures, components, and devices

under programmable control, that is, they are advanced functional nanosystems

that perform atomically precise manufacturing.

The last definition is the clincher. It combines atomic precision (which means

you know the properties of a system at the atomic level and can, given the

position of one atom, know absolutely about the rest of the system) and

programmable control (meaning information is translated into matter assembly).

Atomic precision does not mean "mostly (7,7) carbon nanotubes of more-or-less 20

nm lengths," "chemical reactions of more than 90% yield," "gold nanoparticles of

about 100 nm diameters," or "molecular nanocrystals with about 1000 molecules."

That is not atomic precision, only our current level of control over

matter. I am of the same opinion as

J. Fraser Stoddart,

who described the state of chemistry (in his

Feynman

Experimental Prize lecture) as "an 18 month old" learning the words of

chemistry but unable to speak the short sentences of supramolecular assembly and

simple functional chemical systems, make paragraphs of complex devices from

self-assembling or directed molecules, or the novels that approach the scales of

nanofactories, entire cells, or whatever hybrid system first can be pointed to

by all scientists as a first true productive nanosystem.

Plainly, there is no elegant, highly developed field in

the physical or natural sciences. None. Doesn't exist, and anyone arguing

otherwise is acknowledging that progress in their field is dead in the water.

Even chiseled stone was state-of-the-art at one point.

The closest thing we know of towards the productive nanosystem end is the

ribosome, a productive nanosystem that takes information (mRNA) and turns it

into matter (peptides) using a limited set of chemical reactions (amide bond

formation) and a very limited set of building materials (amino acids) to make a

very narrow range of products (proteins) which just happen to, in concert, lead

to living organisms. The ribosome serves as another important example for the

Roadmap. Atomic precision in materials and products does not mean

absolute positional knowledge in an engineering, fab facility manner. Most

cellular processes do not require knowledge of the location of any component,

only that those components will eventually come into Brownian-driven contact.

Molecular manufacturing proponents often point to the ribosome as "the example"

among reasons to believe that engineered matter is possible with atomic

precision. The logical progression from ribosome to

diamondoid nanofactory, if that progression exists on a well-behaved

wavefunction (continuous, finite -- yeesh-- with pleasant first derivatives), is

a series of substantial leaps of technological progress that molecular

manufacturing opponents believe may/can/will never be made. Fortunately, most of

them are not involved in research towards a molecular manufacturing end and so

are not providing examples of how it cannot be done, while those of us doing

molecular manufacturing research are both showing the potential, and the

potential pitfalls, all the while happy to be doing the dirty work for opponents

in the interest in pushing the field along.

It is difficult to imagine that any single discipline will contain within its

practitioners all of the technology and know-how to provide the waiting world

with a productive nanosystem of any kind. The synthetic know-how to break and

form chemical bonds, the supramolecular understanding to be able to predict how

surfaces may interact as either part of self-assembly processes or as part of

mechanical assembly, the systems design to understand how the various parts will

come together, the physical and quantum chemistry to explain what's actually

happening and recommend improvements as part of the design and modeling process,

the characterization equipment to follow both device assembly and manufacturing:

each of these aspects relevant to the assembly and operations of productive

nanosystems are, in isolation, areas of current research that many researchers

individually devote their entire lives to and that are all still very much in

development.

However, many branches of science are starting to merge and perhaps the first

formal efforts at systems design among the many disciplines are likely to be

considered the ACTUAL beginning of experimental nanotechnology. The

interdisciplinaritization (yes, made that one up myself) of scientific research

is being pushed hard at major research institutions by way of the development of

Research Centers, large-scale facilities that intentionally house numerous

departments or simply broad ranges of individual research. Like research efforts

into atomically precise manufacturing, the pursuit of interdisciplinary research

is a combination of bottom-up and top-down approaches, with the bottom-up effort

a result of individual researchers collaborating on new projects as ideas and

opportunities allow and the top-down efforts a result of research universities

funding the building of Research Centers and, as an important addition, state

and federal funding agencies providing grant opportunities supporting

multi-disciplinary efforts and facilities.

But is that enough? Considering all of the varied research being performed in

the world, is it enough that unionized cats are herding themselves into small

packs to pursue various ends, or is there some greater benefit to having a

document that not only helps to put their research into the context of the

larger field of all nanoscience research, but also helps them draw connections

to other efforts? Will some cats choose to herd themselves when presented with a

good reason?

The Roadmap is not only a document that describes approaches to place us on the

way to Productive Nanosystems. It is also a significant summary of current

nanoscale research that came out of the three National Lab Working Group

meetings. As one might expect, these meetings were very much along the lines of

a typical Foresight Conference, in which every half hour saw a research

presentation on a completely different subject that, because each provided a

foundation for the development of pathways and future directions, were found to

have intersections. The same is true of the research and application talks at

the official SME

release conference. It's almost a law of science. Put two researchers into a

room and, eventually, a joint project will emerge.

On to the Conference

In describing my reactions to the conference, I'm going to skip many, many

details, inviting you, the reader, to check out the Roadmap proper when it's

made available online and, until then, to read through Chris Phoenix's

live-blogging.

As for what I will make mention of...

Pathways Panel

A panel consisting of Schafmeister, Randall, Drexler, and Firman (with Von Ehr

moderating) from the last section of the first day covered major pathway

branches presented in the Roadmap, with all the

important points caught by Chris Phoenix's QWERTY mastery.

I'll spare the discussion, as it was covered so well by Chris, but I will point

out a few important take-homes:

Firman said, "Negative results are a caustic subject... while fusing proteins,

sometimes we get two proteins that change each other's properties. And that's a

negative result, and doesn't get published. It shouldn't be lost." Given the

survey nature of the types of quantum chemical calculations being performed to

model tooltip designs that might be used for the purposes of mechanosynthesis

(molecular manufacturing or otherwise),

Drexler,

Freitas,

Merkle, and

myself spend

considerable time diagnosing failure modes and possibly unusable molecular

designs, making what might otherwise be "negative results" important additions

to our respective design and analysis protocols. Wired readers will note

that Thomas Goetz covered this topic ("Dark Data") and some web efforts to make

this type of data available in Issue 15.10.

I loved the panel’s discussion of replication, long a point of great controversy

over concerns and feasibility. Drexler mentioned how his original notion of a

"replicator" as proposed in

Engines of Creation is obsolete for pragmatic/logistical reasons. But

the next comment was from Schafmeister, who, in his research talk, had proposed

something that performs a form of replication (yes, that's the experimental

chemist making the bold statement); it would be driven externally, but

nonetheless something someone could imagine eventually automating. Christian

also performed a heroic feat in his talk by presenting his own (admittedly, by

him) "science fiction" pathway for applying his own lab research to a far more

technically demanding end, something far down the road as part of his larger

research vision.

Randall, on the use of the Roadmap, said, "The value of the Roadmap will be

judged by the number of people who read it and try to use it. Value will

increase exponentially if we come back and update it." The nature of nanoscience

research is that six months can mean a revolution. I (and a few others at the

very first Working Group meeting) had been familiar with structural DNA

nanotechnology, mostly from having seen

Ned Seeman present

something new at every research talk (that is also a feat in the sciences, where

a laboratory is producing quick enough to always have results to hand off to the

professor in time for the next conference). The Rothemund

DNA Origami paper [PDF] was a turning point to many and made a profound

statement on the potential of DNA nanotech. I was amazed by it. Drexler's

discussions on the possibilities have been and continue to be contagious.

William Shih

mentioned that his research base changed fundamentally because of DNA Origami,

and seeing the complexity of the designs AND the elegance of the experimental

studies out of his group at the Roadmap Conference only cemented in my mind just

how fast a new idea can be extended into other applications. It would not

surprise me if several major advances before the first revision of the Roadmap

required major overhauls of large technical sections. At the very least, I hope

that scientific progress requires it.

Applications Panel

A panel consisting of Hall, Maniar, Theis, O'Neill (with Pearl moderating) from

the last section of the second day covered applications, with short-term and

very long-term visions represented on the panel (again,

all caught by Chris Phoenix).

For those who don't know him,

Josh Hall was the wildcard of the applications panel, both for his far more

distant contemplations on technology than otherwise represented at the

conference and for his exhaustive historical perspective (he can synthesize

quite a bit of tech history and remind us just how little we actually know given

the current state of technology and how we perceive it; O'Neill mentioned this

as well, see below). Josh is far and away the most enlightening and entertaining

after-dinner raconteur I know. As a computer scientist who remembers wheeling

around hard drives in his graduate days, Josh knows well the technological

revolutions within the semiconductor industry and just how difficult it can be

for even industry insiders to gauge the path ahead and its consequences on

researchers and consumers.

Papu made an interesting point I'd not thought of before. While research labs

can push the absolute limits of nanotechnology in pursuit of new materials or

devices, manufacturers can only make the products that their facilities, or

their outsourcing partner facilities, can make with the equipment they have

available. A research lab antenna might represent a five-year leap in the

technology, but it can’t make it into today's mobile phone if the fab facility

can't churn it out in its modern

6 Sigma

manifestation.

Nanoscience isn't just about materials, but also new equipment for synthesis and

characterization, and the equipment for that is expensive in its first few

generations. While it’s perhaps inappropriate to refer to "consumer grade"

products as the "dumbed down" version of "research grade" technologies,

investors and conspiracy theorists alike can take comfort in knowing that there

really is "above-level" technology in laboratories just hoping the company lasts

long enough to provide a product in the next cycle.

O'Neill said, "To some of my friends, graphite epoxy is just black aluminum."

This comment was in regards to how a previous engineering and technician

generation sees advances in specific areas relative to their own mindset and not

as part of continuing advancements in their fields. It's safe to say that we all

love progress, but many fear change. The progress in science parallels that in

technology, and the ability to keep up with the state-of-the-art, much less put

it into practice as Papu described, is by no means a trivial matter. Just as

medical doctors require recertification, scientists must either keep up with

technology or simply see their efforts slow relative to every subsequent

generation. Part of the benefit of interdisciplinary research is that the

expertise in a separate field is provided automatically upon collaboration.

Given the time to understand the physics and the cost of equipment nowadays,

most researchers are all too happy to pass off major steps in development to

someone else.

Closing Thoughts

Non-researchers know the feeling. We've all fumbled with a new technology at one

point or another, be it a new cell phone or a new (improved?) operating system,

deciding to either "learn only the basics" or throw our hands up in disgust.

Imagine having your entire profession changed from the ground up or, even worse,

having your profession disappear because of technology. Research happening today

in nanoscience will serve a disruptive role in virtually all areas of technology

and our economy. Entire industries, too. Can you imagine the first catalytic

system that effortlessly turns water into hydrogen and oxygen gas? If filling

the tank of your jimmied VW ever means turning on your kitchen spigot, will your

neighborhood gas station survive selling peanut M&M's

and Snapple at ridiculous prices?

C-R-Newsletter #57: September 29, 2007

CRN Leadership Expands

A

Successful Nano-Bio Conference

Scenario

Publication Plans

Nanoethics

Questions

CRN Goes to

Hoboken

Journey vs.

Destination

Live-Blogging

Productive Nanosystems

Feature

Essay:

Levels of Nanotechnology Development

Every month

is full of activity for CRN. To follow the latest happenings on a daily basis,

be sure to check our

Responsible Nanotechnology weblog.

==========

CRN

Leadership Expands

The Center

for Responsible Nanotechnology is adding two new

members to its leadership team. Jamais Cascio will become CRN’s Director of

Impacts Analysis, and Jessica Margolin will take on the role of Director of

Research Communities, effective October 1, 2007. CRN co-founder

Chris Phoenix will begin his scheduled sabbatical

in October. Co-founder Mike Treder will continue to

serve as Executive Director of CRN.

“I’ve been

looking forward to this opportunity for some time,” said Phoenix. “With growing

recognition about the importance of molecular manufacturing, with Jamais and

Jessica, two extremely talented people, coming on board, and with Mike’s ongoing

leadership, I feel comfortable taking a sabbatical.”

Jamais

Cascio is a writer, blogger and futurist covering the intersection of emerging

technologies and cultural transformation. He speaks about future scenarios

around the world and his essays about technology and society have appeared in a

variety of print and online publications. He is a fellow at the

Institute for Ethics and Emerging

Technologies, as well as a research affiliate at the

Institute for the Future. He

also works on a variety of independent projects including serving as a lead

author of the recent

Metaverse Roadmap Overview report.

“I’ve

admired CRN’s work for a long time,” said Cascio, “and in recent months I’ve

become more actively involved. Now I’m extremely pleased to be joining the team

in a leadership capacity.”

In 2003,

Cascio co-founded

WorldChanging.com, a Web site dedicated to finding and calling attention to

models, tools, and ideas for building a ‘bright green’ future. Cascio authored

nearly 2,000 articles during his time at WorldChanging, looking at topics such

as energy and the environment, global development, open-source technologies, and

catalysts for social change. In 2006, he started

OpenTheFuture.com as his

online home.

Jessica

Margolin is an entrepreneur who consults in the area of purposeful conversations

and messaging systems. Her professional background includes industry roles in

financial analysis, business development, organizational design, and marketing

strategy and communications; her education includes an MS in Materials Science

in the area of nanotechnology, and an MBA.

“It's

important to ensure all voices are heard during periods of profoundly rapid

scientific innovation,” said Margolin. “Many nanoscale technologies are poised

to be disruptive, and CRN focuses on what is potentially the most disruptive of

all. I look forward to accelerating the development of the community surrounding

CRN's work.”

Currently a

research affiliate at Institute

for the Future, Margolin synthesizes her

professional

experience in the financial and internet industries as well as her

philanthropic work to address problems concerning the design of organizations,

institutions, and communities.

“I’m

ecstatic about the opportunity to work closely with both Jamais and Jessica as

we move forward in the important cause of ensuring safe development and

responsible use of advanced nanotechnology,” said Treder.

A Successful Nano-Bio Conference

From September 10-12, 2007,

CRN was proud to welcome attendees and speakers to our first conference --

"Challenges &

Opportunities: The Future of Nano &

Bio Technologies” -- hosted and co-organized in Tucson, Arizona, by

World Care.

We filled

three days with compelling speakers, panel discussions and novel interactive

collaborations, plus highly enjoyable social hours in the evening. Most of the

conference presentations have been posted online

for free download, and we’ve also offered

short reviews and commentaries on our blog.

To really

get a feel for the content and flow of the event, read the outstanding live blog

coverage provided by Michael Anissimov at

Accelerating Future and by Simone Syed for the

Frontier Channel. Great thanks to all who participated!

Scenario Publication Plans

CRN is pleased to have an agreement with

Nanotechnology

Perceptions, a peer-reviewed academic journal published by Switzerland's

Collegium Basilea, to begin releasing our

nanotechnology scenario series starting with their November 2007 issue. They

will publish two scenarios in that first issue, then follow with two more in

their March 2008 issue, and conclude with the remaining four scenarios in July

2008. Each issue also will include at least one commentary article from a

"European perspective." Simultaneous with the November 2007 issue of the

journal, all eight of our scenarios will be posted online at the

Nanowerk.com

site, where they also will host a discussion space for readers. We're quite

pleased with both of these arrangements; together they will help us to reach a

wide audience for this important project.

Nanoethics Questions

Just what is nanoethics, and why does it matter? That's a

question posed in the Spring 2007 issue of The New Atlantis. Adam Keiper,

the journal's editor, wrote a long article titled "Nanoethics

as a Discipline?" in which he challenged the validity of the field as a

whole and complained specifically about CRN's "many simplistic political and

social assumptions."

CRN wrote a

lengthy rebuttal pointing out the difficulty of stretching towards

understanding in areas where prior work is scant, if it exists at all. At this

stage, we're not ready to go into finer detail with either our analyses or

proposed solutions. Our task for now is to raise awareness of these issues and

to stimulate more comprehensive work by other groups, especially those with

deeper expertise in specific areas.

We also emphatically rejected Keiper’s intimation that because

the future is unknowable, it is therefore uninteresting or unworthy of

speculative exploration. Indeed, it is because we cannot say for sure how

nanotechnology will evolve and how it will affect society that we feel the need

to provoke such discussions. CRN will continue to work on forecasting the future

of nanotechnology, on gaining the facts, on defining our values, and on shaping

politically realistic solutions that give us the best hope for a safe and

responsible world of tomorrow.

Others also had strong responses to Keiper’s provocative article,

including numerous

nanoethics professors and best-selling author David Brin, who wrote a

guest commentary for CRN.

CRN Goes to Hoboken

A few weeks

ago, CRN Executive Director Mike Treder traveled across the Hudson River to

Hoboken, New Jersey, where he presented a seminar on the future of

nanotechnology to graduate students and faculty at

Stevens Institute of

Technology, one of the few universities to offer a

graduate program in

nanotechnology.

Mike said he

was impressed to learn, during sit-down sessions with professors and post-grad

students, about the remarkable work being done at Stevens. It is an institution

on the cutting edge of science and technology, and they show a keen interest in

understanding more about the social implications of their technological work.

Journey vs. Destination

CRN's latest

monthly column for the popular

Nanotechnology Now

web portal has been posted. The current article is titled "Nanotechnology:

Journey vs. Destination" -- here is the abstract:

Nanotechnology has acquired several distinct meanings over the last few

decades. Its development has been marked by this confusion, which has led to

concerns from one field of nanotechnology, molecular manufacturing, being

applied to other fields. As all fields of nanotechnology continue to develop,

molecular manufacturing will reach a point where it is able to accelerate the

other fields.

We hope

you'll read

all our

columns, offer feedback, and tell others about them too.

Live-Blogging Productive Nanosystems

“Productive

Nanosystems: Launching the Technology Roadmap” is the title of an exciting

conference coming soon to Arlington, Virginia (USA), organized by the Society of

Manufacturing Engineers, the Foresight Nanotech Institute, and Battelle. CRN's

Chris Phoenix is planning to attend the October 9-10 event and to "live blog"

his observations for us.

SPECIAL

OFFER: All C-R-Newsletter subscribers are eligible to receive the discounted

member rate -- a $200 savings! When

registering for the conference, enter priority code 07CF308 and member

number 270270 to receive the member rate.

Feature

Essay:

Levels of Nanotechnology Development

Chris

Phoenix, Director of Research, Center for Responsible Nanotechnology

Nanotechnology capabilities have been improving rapidly. More different things

can be built, and the products can do more than they used to. As nanotechnology

advances, CRN continually is asked: Why do we focus only on molecular

manufacturing, when there's important stuff already being done? This essay will

put the various levels of nanotechnology in perspective, showing where molecular

manufacturing fits on a continuum of development -- quite far advanced in terms

of capabilities. Along the way, this will show which kinds of nanotechnology

CRN's concerns apply to.

For another perspective on

nanotechnology development, it's worth reading the section on "The Progression

of Nanotechnology" (pages 3-6) from a

joint committee economic study [PDF] for the U.S. House of Representatives.

It does not divide nanotech along exactly the same lines, but it is reasonably

close, and many of the projections echo mine. That document is also an early

source for the NSF's division of nanotechnology into

four

generations.

The development arc of nanotechnology

is comparable in some ways to the history of computers. Ever since the abacus

and clay tablets, people have been using mechanical devices to help them keep

track of numbers. Likewise, the ancient Chinese reportedly used nanoparticles of

carbon in their ink. But an abacus is basically a better way of counting on your

fingers; it is not a primitive computer in any meaningful sense. It only

remembers numbers, and does not manipulate them. But I am not going to try to

identify the first number-manipulator; there are all sorts of ancient

distance-measuring carts, timekeeping devices, and astronomical calculators to

choose from. Likewise, the early history of nanotechnology will remain shrouded

in myth and controversy, at least for the purposes of this essay.

The first computing devices in

widespread use were probably mechanical adding machines, 19th century cash

registers, and similar intricate contraptions full of gears. These had to be

specially designed and built, a different design for each different purpose.

Similarly, the first nanotechnology was purpose-built structures and materials.

Each different nanoparticle or nanostructure had a particular set of properties,

such as strength or moisture resistance, and it would be used for only that

purpose. Of course, a material might be used in many different products, as a

cash register would be used in many different stores. But the material, like the

cash register, was designed for its specialized function.

Because purpose-designed materials are

expensive to develop, and because a material is not a product but must be

incorporated into existing manufacturing chains, these early types of

nanotechnology are not having a huge impact on industry or society.

Nanoparticles are, for the most part, new types of industrial chemicals. They

may have unexpected or unwanted properties; they may enable better products to

be built, and occasionally even enable new products; but they are not going to

create a revolution. In Japan, I saw an abacus used at a train station ticket

counter in the early 1990's; cash registers and calculators had not yet

displaced it.

The second wave of computing devices

was an interesting sidetrack from the general course of computing. Instead of

handling numbers of the kind we write down and count with, they handled

quantities -- fuzzy, non-discrete values, frequently representing physics

problems. These analog computers were weird and arcane hybrids of mechanical and

electrical components. Only highly trained mathematicians and physicists could

design and use the most complex of these computers. They were built this way

because they were built by hand out of expensive components, and it was worth

making each component as elegant and functional as possible. A few vacuum tubes

could be wired up to add, subtract, multiply, divide, or even integrate and

differentiate. An assemblage of such things could do some very impressive

calculations -- but you had to know exactly what you were doing, to keep track

of what the voltage and current levels meant and what effect each piece would

have on the whole system.

Today, nanotechnologists are starting

to build useful devices that combine a few carefully-designed components into

larger functional units. They can be built by chemistry, self-assembly, or

scanning probe microscope; none of these ways is easy. Designing the devices is

not easy. Understanding the components is somewhat easy, depending on the

component, but even when the components appear simple, their interaction is

likely not to be simple. But when your technology only lets you have a few

components in each design, you have to get the most you can out of each

component. It goes without saying that only experts can design and build such

devices.

This level of nanotechnology will

enable new applications, as well as more powerful and effective versions of some

of today's products. In a technical sense, it is more interesting than

nanoparticles -- in fact, it is downright impressive. However, it is not a

general-purpose technology; it is far too difficult and specialized to be

applied easily to more than a tiny fraction of the products created today. As

such, though it will produce a few impressive breakthroughs, it will not be

revolutionary on a societal scale.

It is worth noting that some observers,

including some nanotechnologists, think that this will turn out to be the most

powerful kind of nanotechnology. Their reasoning goes something like this:

Biology uses this kind of elegant highly-functional component-web. Biology is

finely tuned for its application, so it must be doing things the best way

possible. And besides, biology is full of elegant designs just waiting for us to

steal and re-use them. Therefore, it's impossible to do better than biology, and

those who try are being inefficient in the short term (because they're ignoring

the existing designs) as well as the long term (because biology has the best

solutions). The trouble with this argument is that biology was not designed by

engineers for engineers. Even after we know what the components do, we will not

easily be able to modify and recombine them. The second trouble with the

argument is that biology is constrained to a particular design motif: linear

polymers modified by enzymes. There is no evidence that this is the most